Key factors to consider when looking for a scanning electrochemical workstation.

Latest updated: August 9, 2023Buying a scanning electrochemical workstation: What should you consider?

Modular or single technique scanning electrochemical workstation? Do I need a potentiostat – and if so, which one? How important are the probe types you will use for your scanning electrochemical workstation? This article looks at the different factors that should be addressed when purchasing a new instrument…

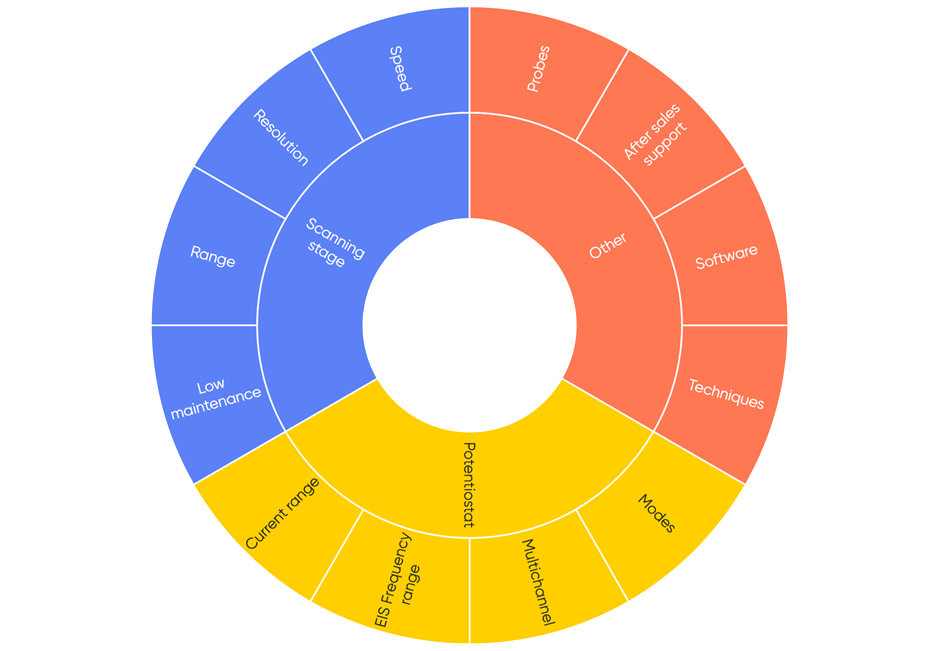

The term scanning electrochemical workstation covers any of a range of instruments containing multiple scanning probe electrochemistry techniques, including, but not limited to, Scanning Electrochemical Microscopy (SECM), Scanning Kelvin Probe (SKP), and Local Electrochemical Impedance Spectroscopy (LEIS). Although not typically used to cover single technique instruments for the purposes of this article, single technique instruments will also be included under the umbrella term scanning electrochemical workstation. Scanning electrochemical workstations are often a long-term purchase, it is common to see instruments still in use 10 or 15 years after their initial installation. With this in mind, careful consideration should be made when selecting an instrument. This article looks to guide users through some of the main factors which should influence the investment in a scanning electrochemical workstation. These factors are illustrated in Fig. 1.

Figure 1: The different factors which should be considered when purchasing a scanning electrochemical workstation are illustrated.

What techniques do you need? The importance of choosing the right system specification for your application(s)

The first consideration when purchasing any scanning electrochemical workstation is whether it can perform the scanning probe electrochemistry technique of interest. Different manufacturers offer different techniques and different combinations of techniques. If multiple techniques are required these could be sourced as multiple standalone instruments from multiple different manufacturers, however, this may not be the most efficient option as it usually requires more space and means buying the same general components more than once. Therefore, in such cases, it is beneficial to consider modular, multi-technique instruments such as the BioLogic M470 scanning electrochemical workstation which will not only save space in your lab, but will also help you streamline your workflow.

However, even when a single technique type is required, considering a modular scanning electrochemical workstation can be beneficial, as this will “future-proof” your instrument and open up significant research opportunities for the future. If the future expansion of a modular instrument to include further techniques is a consideration, the upgrade process should be clarified at the point of purchase. To minimize workflow issues, it is important that the instrument can be upgraded onsite, saving the downtime which would occur if it needed to be returned to the factory for an upgrade.

To find out more about the range of techniques available on a scanning electrochemical workstation, and which technique may be effective for your current or future research check out our article Which scanning probe electrochemistry technique?

Scanning electrochemical workstation specifications: Save time – get it right the first time!

Spatial resolution, scan area and technique/product limits.

Of course, when selecting an instrument, the scanning electrochemical workstation’s specifications must be considered. Will it achieve the desired spatial resolution? Is the scan area large enough for the sample of interest? Is the scan rate fast enough? And so on. When dealing with scanning electrochemical workstation specifications it is worth remembering that it’s not just about the best specifications “on paper”, those specifications also need to be usable. A good example of this is the frequency range of the Lock-In Amplifier (LIA) used in combination with SKP, and other, measurements. Large frequency ranges can be quoted for these as an apparent benefit to the user, however, the frequency range required by a scanning probe measurement is only a small portion of the quoted range. Furthermore, users have no control over the frequency range used by the LIA, as this is all controlled by the backend and therefore the benefit of the expanded frequency range is never felt. Another example is the frequency range available for local impedance measurements, like LEIS, and ac-SECM. Often very low frequencies are possible, so low that it would take days for just a single data point to be measured. Extrapolating this to a full map could mean a single experiment takes months, certainly enough time for the sample to be completely different from the start of the experiment, and any measurement electrolyte to have evaporated away. It can also be important to consider whether a specification is a manufacturer limit or a limit of the technique itself. If the limiting factor is the technique some compromise to the planned experiment may be required.

Potentiostat: If you need one – get the right one!

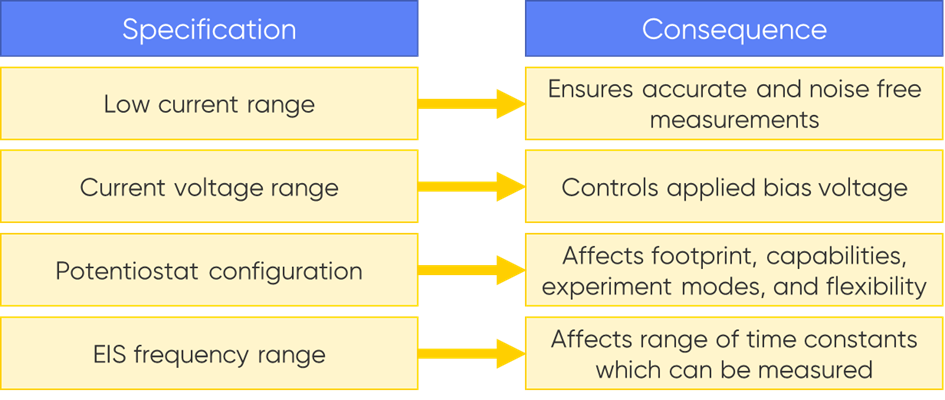

Figure 2 : Key factors when considering the potentiostat of a scanning electrochemical workstation are illustrated.

While not required for all techniques, a potentiostat is required for most scanning probe electrochemistry techniques and lies therefore at the heart of many scanning electrochemical workstations. The key specifications to consider for the potentiostat are the low current ranges (which will ensure that the nA currents common in SECM, for example, can be measured accurately without substantial noise), the control voltage range (which impacts the bias voltage that can be applied), and the modes the potentiostat can be used in (for example whether it is capable of performing impedance measurements). For SECM specifically, which can require the use of a bipotentiostat, it can be useful to consider how the bipotentiostat is implemented. This varies between instruments and can be achieved with a two-channel potentiostat, the use of two separate potentiostats, or with a potentiostat with a slave channel. How the bipotentiostat is implemented can affect the capabilities and footprint of the system. Although not always possible it can be useful to consider whether the scanning electrochemical workstation of interest can be used with an existing potentiostat, which can be a great way to expand on the capabilities of an existing instrument. On the other hand, if the full scanning electrochemical workstation is purchased with the potentiostat, you should definitely ask yourself the question: “can this potentiostat be used as a stand-alone instrument?”. This gives the scanning electrochemical workstation another life, even when not in use for scanning probe electrochemistry experiments. Finally, when considering the potentiostat used with the scanning electrochemical workstation it can be beneficial for this to be proprietary to the scanning electrochemical workstation manufacturer, as this allows after-sales service of the entire system to be handled by a single manufacturer.

Fig 3: The consequences of the different potentiostat specifications are shown.

Scanning stage: Speed, length, resolution, and ongoing maintenance

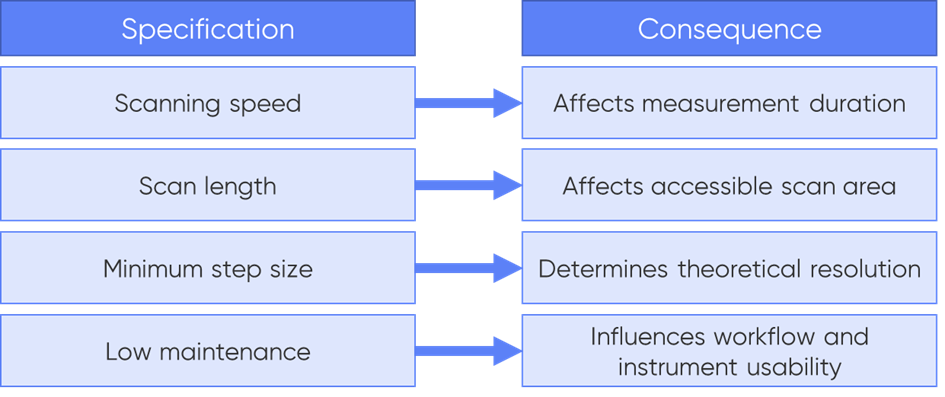

Figure 4: Key factors of the scanning stages of a scanning electrochemical workstation are illustrated.

Without the scanning stage, a scanning electrochemical workstation does not exist. When looking at the scanning stage, key specifications to consider are the scanning speed (which will impact the experiment time), the scan length (impacting the accessible scan area), and the positioning resolution (although this value is often much smaller than the practical resolution achievable due to limits on the probe size). While the emphasis is often put on the type of drive system used, this is often misguided thinking. High-accuracy and high-resolution on long-range scanning systems are achievable on a variety of drive systems from stepper motors to piezo walkers when care is taken to optimize the position measurement and control. For high accuracy and resolution what is more important is that a closed-loop system is used, as this allows the position to be continuously measured by an additional measurement tool removing even small errors. It is also important to consider the maintenance levels required by the positioning system. If the drive components are enclosed this will shield the positioning system from dirt and dust, reducing the maintenance required, extending the lifetime of the positioning system, and maintaining positioning accuracy.

Figure 5: The consequences of the different specifications of the scanning stage are shown.

Probes for scanning electrochemical workstations: Outsource or do it yourself? What works best?

The probe is key to any scanning probe electrochemistry experiment controlling measurement quality and resolution. Most manufacturers will include at least one probe with a new system; however, it is expected that during the lifetime of an instrument these will need to be replaced, with the frequency dependent on the technique and experiment conditions. Advanced users of a system may decide to make their own probes. In this case, it is important to know whether there are provisions in place to be able to do so, most specifically with regards to the connection of the probe to the scanning electrochemical workstation electronics (electrometer, or potentiostat depending on the technique). Users who make their own probes are often in the minority, with many opting to purchase probes for use with the scanning electrochemical workstation. In this case, it is important that the probes of interest are readily available from the manufacturer, or a third-party. Some manufacturers ship probes ready to use and fully characterized, while others require some prep work to be used. It is important to understand the level of work required to use a new probe, and what care is required to continue to properly use the probe.

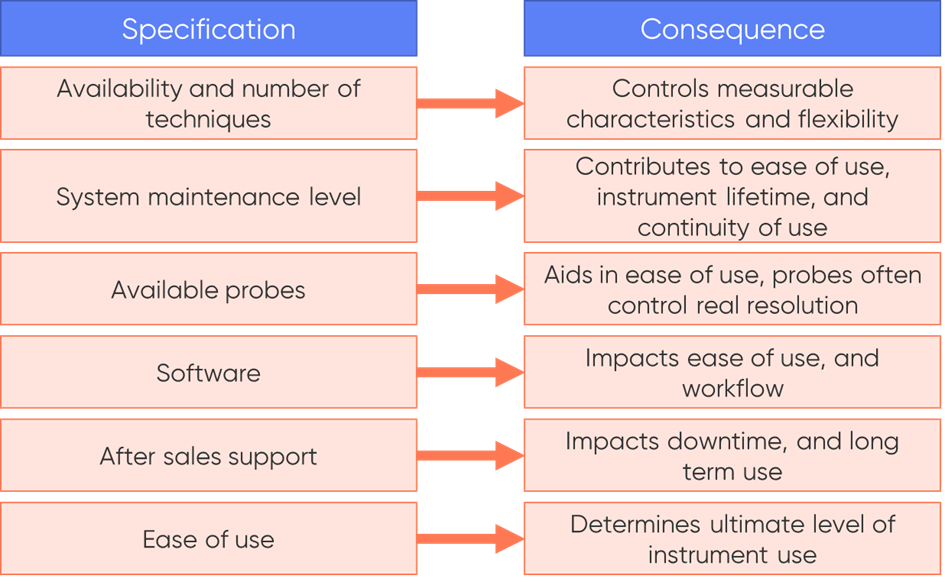

Software: Are all techniques covered in one package?

When selecting a scanning electrochemical workstation, the hardware may seem the most important thing to consider, but the software should not be a secondary consideration. The software can affect the user experience considerably, and therefore is almost as important as the hardware itself. The scanning electrochemical workstation software should be easy to learn even for someone new to scanning probe electrochemistry. If the software is difficult to use, this can discourage use, and present a barrier to running more than just a basic experiment. While some software allows access to every possible variable this is not always beneficial to a user, making it difficult to intuit how the software works, and how different variables can affect the measurement. It is highly beneficial for all experiment types, scanning, electrochemical, and impedance-based, to be contained within a single software package. Often in scanning probe electrochemistry techniques, users are doing more than just scanning. As an example, a user may start an SECM study with a cyclic voltammogram of the probe, perform cyclic voltammetry on the sample, approach to the sample surface, and run an area scan, this may finally be followed by a number of cyclic voltammograms, or even electrochemical impedance spectra, at certain features across the surface. If users cannot perform all of these experiment types in one software package they could find they are constantly flipping back and forth between software, impacting workflow and usability. Furthermore, having everything in one software allows a degree of automation with it possible to sequence both electrochemistry and impedance measurements, and scanning measurements.

After-sales support: Is your supplier in it for the long-term?

Scanning electrochemical workstations are highly technical instruments with many different parts and a long lifetime. When selecting a scanning electrochemical workstation, it is important to consider the maintenance levels needed to keep the instrument in good working condition. If an instrument is high-maintenance, users may become frustrated with the effort required to continue running routine experiments. Even for low maintenance, high-quality instruments, consideration should be given to what happens if something goes wrong. It is important for such instruments that there is a high level of technical support for existing users. The support should also be responsive to issues that arise, and handle repairs efficiently. Selecting an instrument with a low level of support is not an issue when everything is working, but if something goes wrong it could result in costly downtime later.

After-sales support does not just cover the response when things go wrong, it also includes anything to help users get the most out of their instrument. The high level of technical support which exists for solving an issue should exist for practical questions from a user. The technical nature of scanning probe workstations means effective media should exist to help users learn the instrument and any techniques available. For those looking to do more than a basic experiment, it is also essential to access media, in the form of notes, videos, or blog posts, which describe more advanced uses. Once a scanning electrochemical workstation is purchased the level of support available to users can have a real impact on its effective long-term use.

Users: Who will be using the scanning electrochemical workstation?

The final consideration which must be made when selecting a scanning electrochemical workstation concerns the future users of the scanning electrochemical workstation, which will have a real impact on how some of the factors already discussed must be approached. For users completely new to scanning probe electrochemistry one of the most important factors in selecting an instrument may be the ergonomics of the system and how easy it is for them to learn and use in the long term. If, however, users already have advanced knowledge of the scanning probe electrochemistry technique of interest, ease of use may have little or no bearing when selecting an instrument. It can also be important to consider whether the instrument will have the same main user for its lifetime or if this could change. If the user changes and internal support is not available this will need to come from the after-sales support of the manufacturer. With this in mind it can be important to consider training media, e.g. help files and videos, available from the manufacturer, and even if there are options available for future live training sessions. In the end, if users are unable to work with the instrument its effective lifetime will be greatly reduced.

Figure 6: Other specifications of merit when purchasing a scanning electrochemical workstation are outlined.

Strengths of the M470 scanning electrochemical workstation

BioLogic’s M470 scanning electrochemical workstation addresses many of the key aspects outlined in this article. The M470 is BioLogic’s 4th generation scanning electrochemical workstation. It can contain up to nine different techniques, with upgrades from any initial configuration available on-site. The M470 has been designed with scanning measurements in mind, making the M470 low maintenance and user-friendly. The control electronics are self-contained, with most connections made internally, reducing the possibility of cross-connections due to user error.

Furthermore, the scanning stages are almost entirely enclosed excluding the effects of dirt and dust on the positioning system and increasing their working life. The M470 is most commonly combined with our Premium range SP-300 potentiostat, which can be used with or without the scanning electrochemical workstation. All experiment types are performed in a single proprietary software, which can be used by both new and experienced users. To help users learn the different techniques and build from basic experiment types BioLogic has an ever-growing range of media from videos to short articles for users to consult. And if any questions or issues arise, our support team is here to help users get the most out of their instruments.

Conclusion: Your scanning electrochemical workstation is an important investment – choose wisely!

Although not necessarily exhaustive this article has addressed some of the key aspects of a scanning electrochemical workstation that should be considered during its purchase. These include obvious factors like the techniques available, and the instrument specifications, and also less obvious factors like the after-sales support available and the people who will be working with the instrument.

If you want help on your journey purchasing a scanning electrochemical workstation, why not contact your local BioLogic representative.

|

Scanning electrochemical workstation considerations |

M470 |

| Modular instrument (flexibility to upgrade new techniques easily onsite)? | YES: Wide range of techniques available:

SECM(ac/dc), ic-SECM, LEIS, SVP, SKP, SDS, OSP. These can be ordered with the M470 at point of purchase, or easily upgraded in your lab at a later date. |

| Comes with proprietary potentiostat which can be used as a standalone instrument – opening up new scientific opportunities? | YES: The M470 has been designed to fully exploit the numerous advantages of the BioLogic SP300 potentiostat and its benchmark EC-Lab control/analysis interface. Low current range (100 pA to 1A) ensures nA currents common in SECM, can be accurately measured without significant noise. |

| Closed-loop positioning system for high accuracy and resolution? | YES: Closed-loop system provides a secondary measurement tool to optimize measurement accuracy. Furthermore, drive components are enclosed to facilitate maintenance and extend the positioning system lifetime/maintain positioning accuracy. |

| Are the necessary probes supplied? | YES: The M470 is supplied with all necessary accessories to begin running experiments straight away, including probes. For SECM and SKP multiple probe sizes are offered to allow users flexibility in measurement resolution. Options to use the M470 with home-built probes are also available. |

| User-friendly software covering all techniques in one package? | YES: The M470 control software governs all techniques meaning users can easily transition from one technique to another. User-friendly, it includes 40 discrete experiments, each with individual variations. An integrated user-help library is included to provide instant support. |

| Customer support? | HIGH: Large online database of over 80 support documents including user manuals, technical notes, application notes and tutorials, and support videos are available.

Online and telephone support is available. |

For more information on scanning electrochemical workstations

Related products