Probing 2D Materials

Latest updated: June 2, 2023Almost a decade ago, in 2010, the Nobel Prize in Physics was awarded for the isolation of graphene. Publications in the field of 2D materials have grown exponentially since graphene’s initial isolation in 2004. It is also estimated that the market for 2D materials will reach $390 million by the mid-2020s. The extraordinary interest in 2D materials has arisen because of their exceptional properties, particularly their electrical and mechanical properties. As such 2D materials, like graphene, graphene oxide and MoS2, are being investigated for their application in fields including, but not limited to:

• Flexible and wearable electronics

• Batteries

• Sensors

• Piezoelectrics

• Catalysis

2D materials have been investigated using traditional electrochemical methods, providing a global view of the 2D material under investigation. Using traditional electrochemical methods however hides the intricacies of 2D materials. These single atom thick materials are composed of the basal plane, i.e. the plane parallel to the 2D material plane, and the edge plane, i.e. the plane perpendicular to the 2D material plane. They also may have surface disorder including steps, defects, and crevices. All of which give rise to varied electrochemistry throughout the material, which could be exploited, for example, for catalytic processes. Therefore, while bulk electrochemical measurements can provide a useful starting point for investigations into the electrochemical activity of 2D materials this fails to paint a full picture.

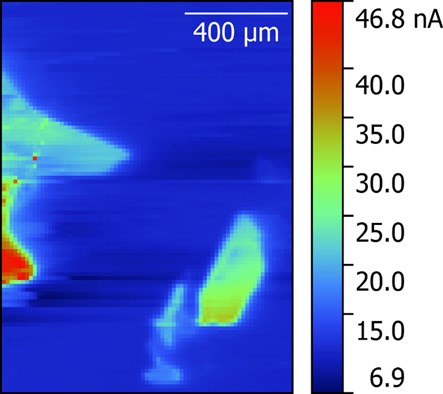

Graphite flakes measured by height tracking-SECM in n 5 x 10-3 mol L-1 KI and 0.1 mol L-1 KCl

So how can we get an accurate picture of 2D materials?

Scanning probe electrochemistry provides us with the means to produce localized electrochemical measurements that can be correlated to sample features, including relating enhanced electrochemistry to edge sites. This is a varied toolkit, however of particular interest for 2D materials is Scanning ElectroChemical Microscopy (SECM). In most SECM experiments the interaction of an electrochemically active species in solution, known as the redox mediator, with the sample of interest is monitored by a biased ultramicroelectrode probe which is in close proximity to the sample surface. The signal measured by the probe is ultimately determined by the activity of the sample with regards to the redox mediator, with a stronger signal measured for more active samples. In SECM it is also possible to impose a current on the sample. Due to the principle of operation of the SECM measurement it can be used to examine, analyse and even alter the surface of the sample of interest. SECM can be implemented on both the SECM150 and M470 instruments.

While any of the six other scanning probe electrochemistry techniques available from Bio-Logic will provide local information about the 2D material of interest, SECM provides a number of distinct advantages.

- Unlike traditional techniques used to measure the conductance of 2D materials, and indeed other scanning probe electrochemistry techniques, SECM does not require electrical contact to be made to the sample. This is particularly advantageous because it simplifies the interpretation of the conductivity data with the contact resistance between the 2D material and underlying substrate no longer needing to be accounted for. Furthermore, this avoids any damage caused by contacting the 2D materials.

- SECM has been routinely used to perform local kinetics studies in a variety of fields. In the field of 2D materials studies of this kind can be extended to the investigation of local conductivity. Unlike traditional conductivity experiments which investigate the average conductivity, and can be associated with large uncertainties as a result of sample inhomogeneity, SECM by its nature accounts for the inhomogeneities in the 2D material. Using SECM, therefore, it is possible to investigate the effects of edges, surface defects, overlapping flakes, and other inhomogeneities, on the conductivity. Understanding how these surface features influence conductivity it can be possible to tune 2D materials to exhibit more of the characteristics we want.

- When SECM is used the probe alone dictates the measurement resolution. With probes as small as 1 µm available, and the possibility to connect home-built probes, SECM provides superior resolution compared to other scanning probe electrochemistry techniques.

- SECM is uniquely positioned in that it can be used to modify samples through the application of a localized bias by the probe. This means that the 2D material could be modified, and the effect of the modification examined, all in a single experimental setup.

- SECM has inherent chemical selectivity. This can be particularly useful for investigating the application of 2D materials as catalysts.

With a growing interest in the application of 2D materials to a wide range of fields methods to fully characterize these materials is necessary. SECM can provide a unique perspective of 2D materials to help us more effectively implement them in the future.

Feeling inspired to use SECM to investigate 2D materials?

SCAN-Lab AN#17: The use of height tracking SECM to measure mechanically exfoliated graphite will provide you with more information to help you get started with your own SECM measurements on 2D materials. In this note we introduce the use of SECM to measure local activity differences across graphite flakes provided by the University of Manchester. Due to the flat nature of these samples, and other related 2D materials, it is important to minimize the effect of sample tilt on the measurement. In this note we minimize the effects of sample tilt through Height Tracking-SECM based on a background measurement initially achieved through Intermittent Contact (ic)-SECM.

To learn more about the SECM systems available from Bio-Logic please visit the M470 and SECM150 pages.

Find out more about BioLogic and scanning probe electrochemistry...

Related products

These products may help you go further with you research.