Data of interest – work more efficiently.

Latest updated: June 2, 2023Data of interest: Introduction

Electrochemistry is not just about time, current & voltage. The variable process is a set of automated EC and BT Lab potentiostat and battery cycler software functions that can save you valuable time in identifying key data of interest such as battery cycle life, Coulombic efficiency, capacity fading, Ohmic drop, and $\mathrm{d}Q/\mathrm{d}E$, etc.

The potentiostat/galvanostat, that inimitable Swiss Army knife of electrochemical research. We would be lost without it. For years the instruments have been used to better understand the mysterious relationships between time, current and voltage; helping us break down scientific boundaries, develop new products – batteries and other innovations in order to optimize circuits amongst a myriad of other applications and uses.

But, in fact, the instruments can be used for so much more and are often under-exploited. BioLogic’s potentiostats (sometimes referred to as electrochemical workstations) and their control software EC-Lab® and BT Lab® have been designed with a huge range of highly advanced functionality that can be used to help you generate data of interest; data such as Efficiency, $Q_{discharge}$, $Q_{charge}$ and capacity that can play a vital role in advancing your research.

Data of interest for potentiostats and battery cyclers

Accuracy and autonomy

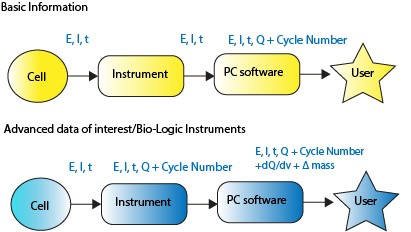

The main difference between data originating from PC software calculations and from instrument calculations is the frequency of calculation. Data processed in the software (in the PC) are dependent on points obtained from the potentiostat / galvanostat i.e., the sampling rate chosen by the user in the corresponding technique. Then, only data corresponding to the sampling rate is sent to the computer. Data originating from the instrument are only dependent on the time base of the instrument – 200 µs for essential and premium range potentiostat, and not on the sampling rate set. So, this results in more accurate data

Furthermore, this allows the instrument to remain autonomous even in the case of computer or PC-instrument communication failures. Safety or experimental limitations can be triggered even if the computer cannot be reached.

There are two types of variable process available in BioLogic’s potentiostat and Battery cycler ranges:

| Usual Online and post processed variables | Automatic : Limits or parameters injection | Non-Automatic: analysis |

| $Q-Q_0$: charge from the beginning of the experiment | X | |

| $Q_{charge}$ for a charge sequence, reinitialized every cycle cycle | X | |

| $Q_{discharge}$ for a discharge sequence, reinitialized every cycle | X | |

| Efficiency: $Q_{discharge}/Q_{charge}$ | X | |

| $x$ : normalized charge | X | |

| $\mathrm{d}Q/ \mathrm{d}V$ : differential capacity | X | |

| Ohmic drop compensation | X | |

| Cycle number | X | X |

| Power: in CPW, calculated by $E\times{I}$ | X | |

| Energy: in CPW calculated by $E\times{I}\times{t}$ | X | |

| $E_{charge}$ and $E_{discharge}$: | X |

BATTERY APPLICATIONS

Variable process: Identify Battery Cycle Life more quickly and with increased precision

Take the example of battery applications where the automatic variable process is most applicable. The initial capacity of a battery, capacity fade during use, the capacities at several charge/discharge rates and Cycle Life are all fundamental research values needed at practically every level of the battery-development value chain. Therefore, one would assume, this information is easy to identify. Unfortunately, this is often not the case.

BioLogic’s EC-Lab®/BT-Lab® potentiostat and battery cycler interfaces, however, can give you access to this data, quickly and easily via its variable process functionality.

An accurate starting point, an automated process and increased precision. Only on EC-Lab

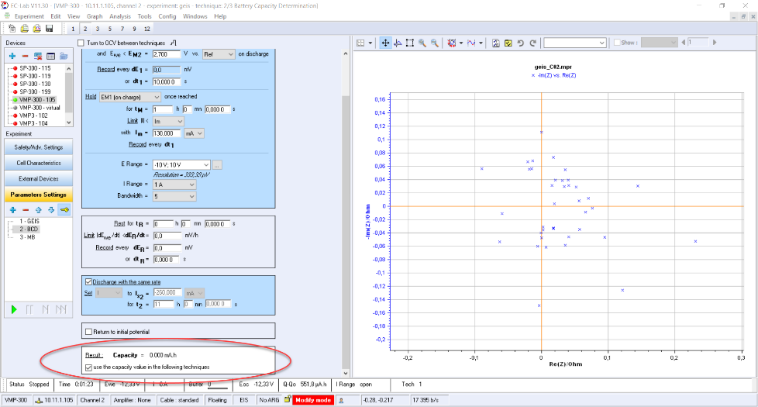

The starting point is BCD (Battery Capacity Determination) which ascertains the correct, non-arbitrary, capacity of the battery by performing a galvanostatic discharge. Once this figure has been determined, the system will start automatically cycling your battery, calculating the exact current corresponding to an arbitrary C-Rate down to a predetermined cut-off voltage. In an environment where test cycles of 5K (or more) are common, the automated nature of this capacity determination process not only makes life easier for users working on battery testing but also increases the precision of such results significantly. It is easy to generate such data and we have put together a video tutorial, which can be found at the bottom of this article, to take you through each individual stage of the process.

|

|

|

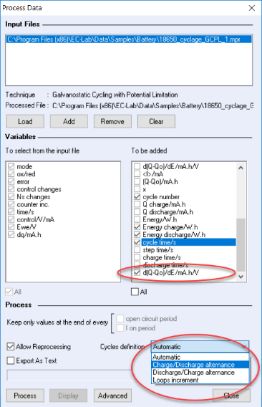

| Figure 1: illustrates non- automatic post-process data → allows alternative cycle definition, $E_{charge}$ and $E_{discharge}$:(only BL) | Figure 2: illustrates automatic capacity determination re-injected in the next technique → allows C-rate automatic correction or new charge limit |

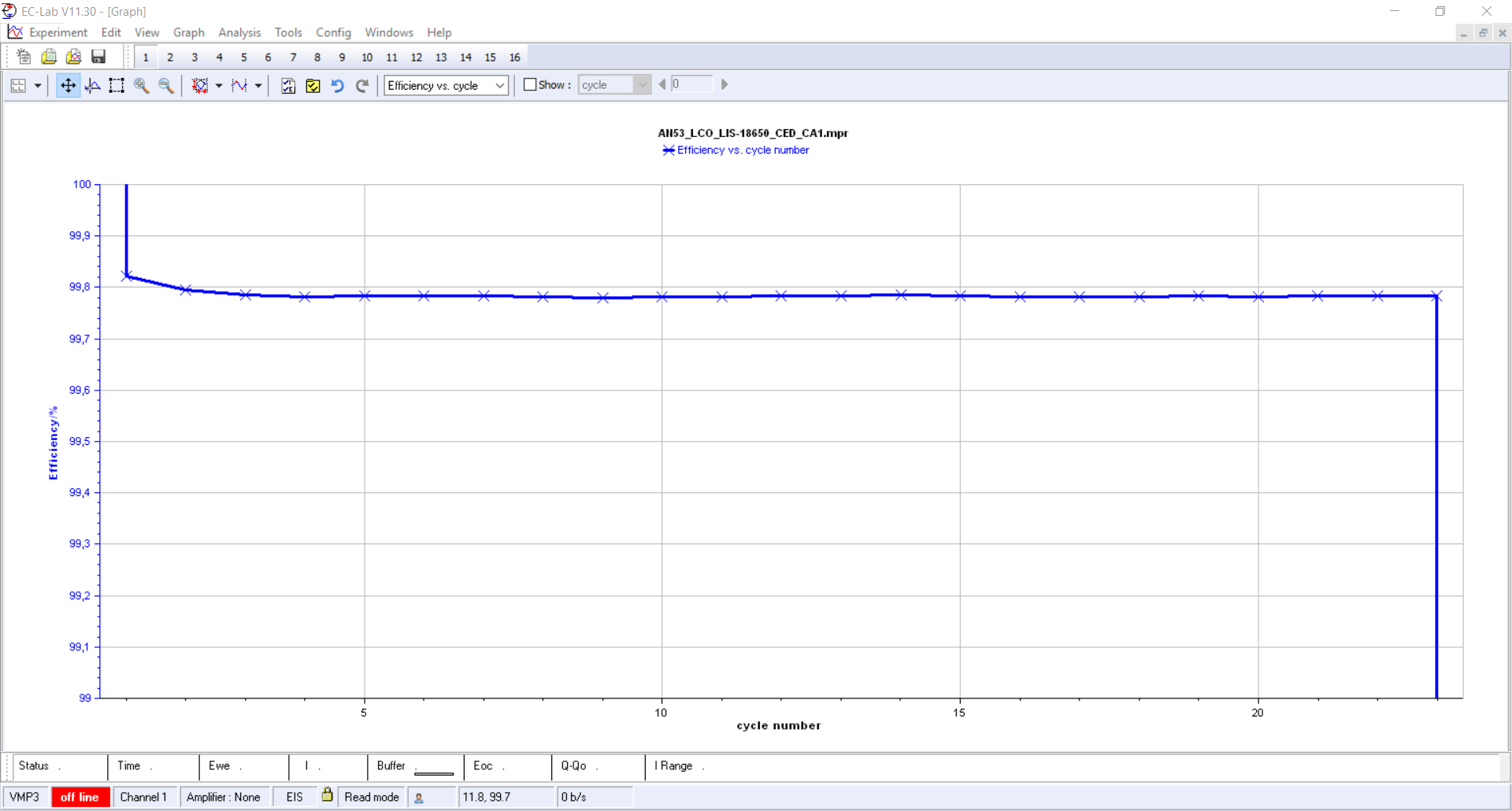

Figure 3: illustrates automatic Coulombic Efficiency calculation → allows plotting Eff vs cycle number |

At a glance…

- Fully automated process for ascertaining battery cycle life data

- Increased precision/reduced lead time

- Applicable for other key areas such as determining Coulombic Efficiency, specialist battery chemistries such as silicon batteries, capacity fading, Ohmic drop, and dQ/dV

- Only available on BioLogic’s EC/BT-Lab interface

Ref 1 : For more information, please see Technical note: TN 38

Ref 2 : Click on the video tutorial to find out more.

The following articles related to data of interest may be of use....

Related products