Corrosion R&D Solutions.

Precision tools for corrosion research — from industrial standards to advanced studies.

Comprehensive solutions for corrosion research and industrial applications.

Corrosion research spans from standardized testing to cutting-edge investigations. Each research area demands specialized instruments and techniques. Whether you’re validating materials against industry standards or exploring novel corrosion mechanisms, we have the right solution for your specific application. Explore typical configurations from our comprehensive, modular portfolio and connect with our sales experts to design the perfect solution.

Industrial Standards

“I need to comply with industry standards and validate material performance.”

Meeting industry requirements is fundamental to material qualification and regulatory compliance. Whether you’re testing according to ASTM, ISO, or specific industry protocols, you need instruments that deliver reliable, reproducible results that stand up to scrutiny.

Advanced Studies

“I’m pushing the boundaries of corrosion science with sophisticated experiments”

You need advanced capabilities to understand complex corrosion phenomena. When standard procedures can lead to surface destruction, take too long, or do not provide the information you need, advanced instruments and techniques should be considered. Whether investigating multi-component systems, extreme environments, or novel materials, your research demands the most sophisticated electrochemical instrumentation and analysis.

Local Investigations

“I need to understand corrosion at the microscale level”

Corrosion often begins at specific sites—grain boundaries, inclusions, or surface defects. Understanding these localized phenomena requires techniques that can probe corrosion behavior with high spatial resolution while maintaining electrochemical precision.

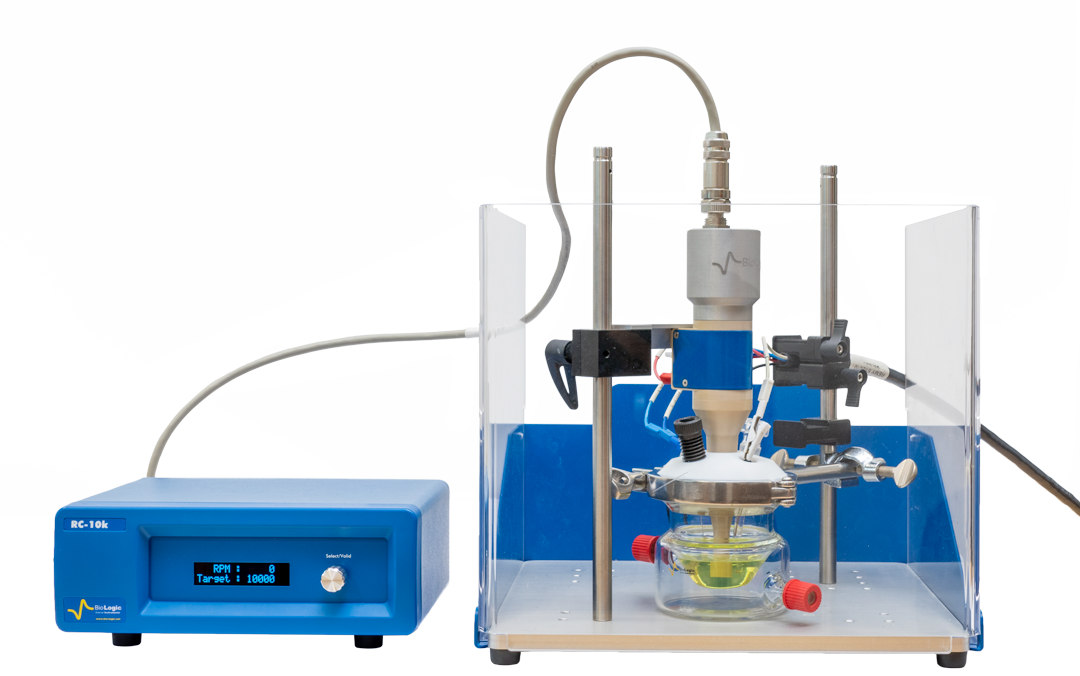

Kinetic Studies

“You need to understand the rates and mechanisms of corrosion processes”

Corrosion kinetics determine how fast materials degrade and under what conditions. Whether you’re studying inhibitor effectiveness, temperature dependencies, or reaction mechanisms, you need precise control over experimental conditions and ultra-sensitive measurement capabilities.

Ready to start your journey or move to the next stage?

Request a quote and take advantage of our personalized advice and get the data you need to make informed decisions.

FAQ.

Which standard protocols are available for corrosion testing?

With BioLogic’s potentiostats, EC-Lab software provides 6 techniques in compliance with ASTM and JIS standard procedures: Linear Polarization Resistance technique (ASTM-G59), Electrochemical Noise technique (ASTM-G199), Galvanic coupling technique (ASTM-G71), Cyclic Potentiodynamic Polarization technique (ASTM-G61), Critical Pitting Temperature technique (ASTM-G150) and Repassivation Potential technique (JIS 0592). Learn more here.

And for even more information and guidance your local BioLogic representative is here to help.

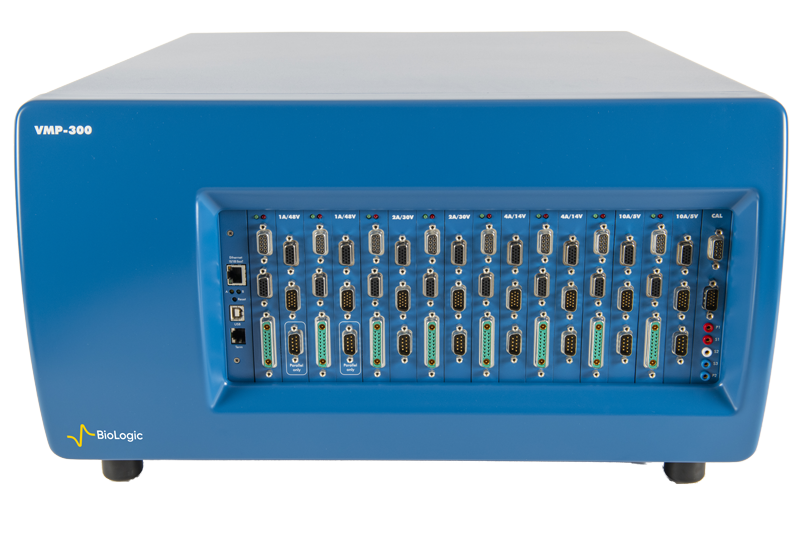

I’m interested in high throughput screening for material selection, what do you offer?

BioLogic’s multichannel potentiostats can be used to perform high throughput screening experiments. Users can take advantage of their ability to setup multiple cells and tests for simultaneous experiments, learn more here.

Scanning Electrochemical Microscopy (SECM), and Scanning Droplet Cell (SDC), available on the M470, can also be used in high throughput screening. These techniques are used because of their ability to obtain local information and therefore measured individual samples of a library at each step of an experiment. Further information on high throughput screening can be found in our Learning Center article Introduction to High Throughput Screening.

For help in choosing the right solution for you, we recommend contacting your local BioLogic representative.

How to determine corrosion resistance of coatings? (high impedance coating measurements)

Electrochemical Impedance Spectroscopy (EIS) is a non-destructive technique that can be used to characterize coatings and corrosion protection effectiveness. EIS can track coating degradation by measuring changes in impedance response over exposure time. EIS is a powerful tool that can be valuable for quality control and failure analysis.

For high impedance coating, BioLogic Premium potentiostat can be equipped with ULC-z cable to assess ultra low current and ensure precision for these ultra-sensitive measurements. To help you conduct reliable EIS measurements, our experts have developed quality indicators (EIS QI™), notably the NSD to check the time variance of your system.

For help in choosing the right solution for you, we recommend contacting your local BioLogic representative.

How can I test biocorrosion with electrochemical method?

Classical electrochemistry techniques such as linear polarization measurements, electrochemical impedance spectroscopy (EIS), and electrochemical noise (EN) can be used. Even if these methods have not been explicitly designed for biocorrosion analysis, they can be implemented. Learn more here.

And for even more information and guidance your local BioLogic representative is here to help.

Read the article

Read the articleA local view of corrosion

The effects of corrosion need to be considered in almost every industry. A recent NACE report [1] estimated that corrosion costs $2.5 trillion USD globally

Read the article

Read the articleHow to decode the standard test methods for corrosion?

This article discusses corrosion techniques available in EC-Lab in compliance with ASTM and JIS standards.

Read the article

Read the articleReduce parasitic impedance on high impedance measurements

This article discusses corrosion techniques available in EC-Lab in compliance with ASTM and JIS standards.