Fuel Cell & Electrolyzer R&D Solutions.

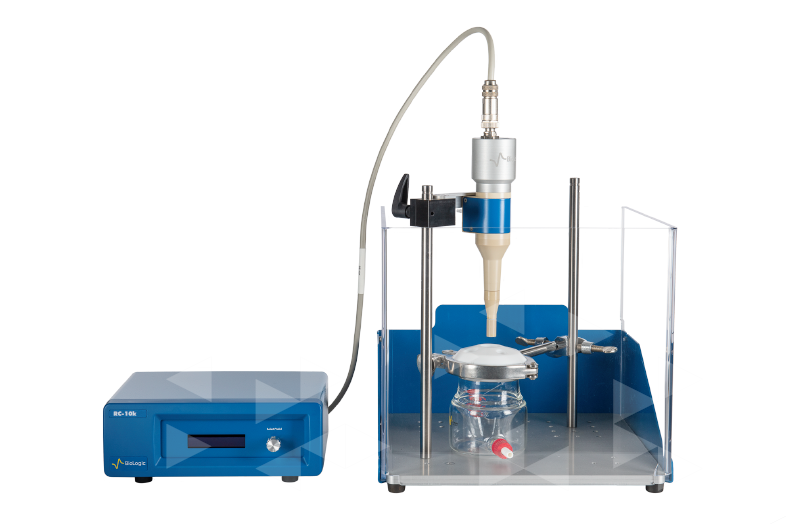

Precision tools for every stage of fuel cell and electrolyzer R&D — from materials to small stack validation.

Your Complete Fuel Cell & Electrolyzer Development Journey

From R&D to production, our electrochemical testing instruments addresses critical challenges across every stage of fuel cell and electrolyzer development. For gas and fluidics control, our BluPEM fuel cell and electrolyzer workstation is fully customizable to deliver the perfect solution to your need. Explore typical configurations from our comprehensive, modular portfolio then connect with our sales experts to design the perfect solution.

Materials & Components Research

“I need to understand catalyst performance at the local level and screen new materials efficiently”

At the foundational level of fuel cell and electrolyzer development, you’re investigating fundamental questions about catalyst activity, material combinations, iteration performances, and variations across the electrode surface.

Small Cell Investigations

“I have promising materials, now I need to build and test actual fuel cells or electrolyzers”

Moving from materials to working devices brings new challenges, from determining how your materials perform in a complete cell to finding optimal operating condition and balancing performance with durability

Large Cell Investigations

“I need to validate performance at realistic sizes and current densities”

Scaling up reveals new phenomena: How do current distributions affect performance? What about thermal management? How do I maintain uniformity across larger electrode areas?

Studying Small Stacks

“I’m ready to move beyond single cells to multi-cell stack configurations”

Stack development introduces complexity: How do individual cells interact? How do I monitor each cell’s contribution? What about stack-level optimization?

Complete Test Stations

“I need to control the gas and liquid flow environment around my cells/small stacks and to synchronize electrochemical characterization”

Fuel cell and electrolyzer performance are very sensitive to flow, humidity, temperature and pressure changes: How does my cell behave when changing parameters? How does my cell/stack age? How do individual cells interact? How do I monitor each cell’s contribution?

Ready to start your journey or move to the next stage?

Request a quote and take advantage of our personalized advice and get the data you need to make informed decisions.

FAQ.

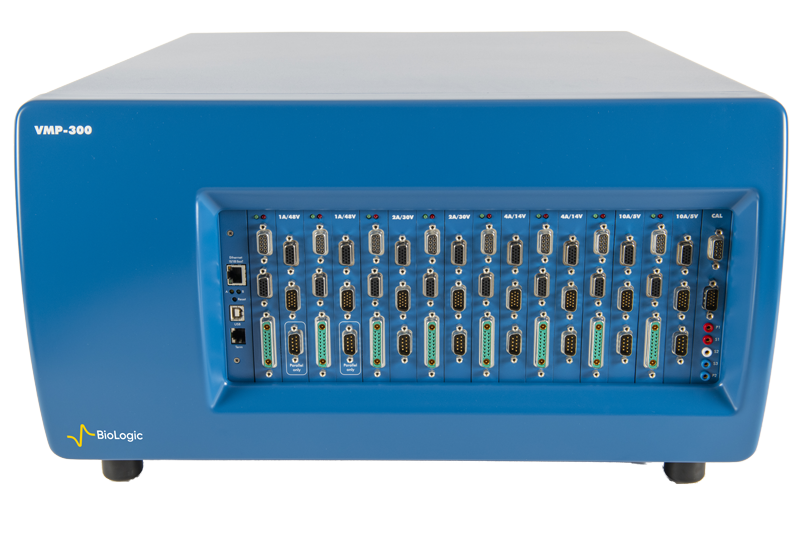

What if my research needs change? I am working with single cells now, but in the future, I plan to work on short stacks, can my potentiostat grow with me?

A range of Premium boosters are available with different current and voltage ranges. They connect directly into the instrument chassis, with a plug-and-play approach making it easy to update your instrument. The addition of boosters can be done yourself at any point, not just at time of purchase, so your potentiostat can easily grow with you.

Find out more in our Learning Center article: Future proof your potentiostat with Premium range, self-install internal boosters. And for even more information and guidance your local BioLogic representative is here to help.

Can my potentiostat be integrated into a commercial or homemade bench station?

EC-Lab® offers a developer package for OEM integration, allowing potentiostat control from your own software. For further information we recommend reading section 3 of EC-Lab® solutions for coupling with external devices, and contacting your local BioLogic representative.

Is there a solution for high throughput screening of fuel cell catalysts?

BioLogic’s multichannel potentiostats can be used to perform high throughput screening experiments. Users can take advantage of their ability to setup multiple cells and tests for simultaneous experiments, or they can couple them with a multielectrode array for simultaneous experimentation. Furthermore, utilizing the EC-Lab® developer package to combine BioLogic’s potentiostats with more complex setups, such as those performing automated serial measurements.

Scanning Electrochemical Microscopy (SECM), and Scanning Droplet Cell (SDC), available on the M470, can also be used in high throughput screening. These techniques are used because of their ability to obtain local information and therefore measure individual samples of a library at each step of an experiment.

Further information on high throughput screening can be found in our Learning Center article Introduction to High Throughput Screening. For help in choosing the right solution for you we recommend contacting your local BioLogic representative.

Can the fuel cell be measured in a stack?

Stack experiments are available for VMP-3 based instruments, with stack mode available in EC-Lab. Using the SAM-50 users can study stacks of fuel cells up to 60 V. In stack mode the current through the whole stack is the same as the current through each element, while the voltage through the whole stack is the sum of each element. The main channel controls the current through the whole stack, while the auxiliary channels measure the voltage of each element. For further information on how BioLogic’s instruments and software allow design of experiments to study fuel cell stacks please see our Learning Center article: Optimize Pack and Stack Performance with Simultaneous Measurements.

Read the article

Read the articleElectrochemical characterisation of fuel cells and electrolysers

This article explains the electrochemical characterization of fuel cells and electrolysers using DC and AC techniques.

Read the article

Read the articleScanning Probes & Fuel Cell Research

Scanning Probes & Fuel Cell Research: overview of techniques

Read the article

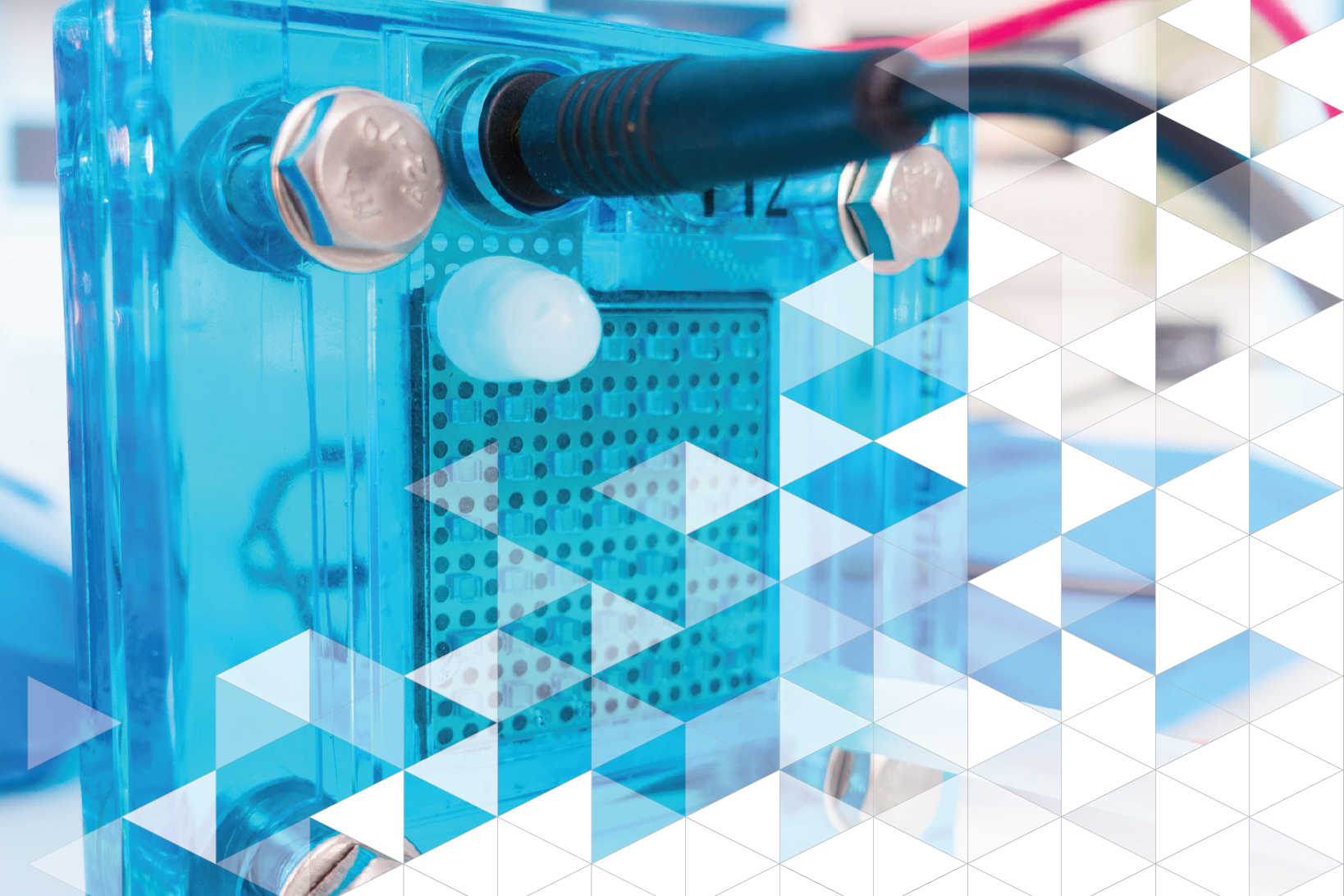

Read the articleWhat are PEM Fuel Cells and Electrolyzers?

This article will explain the basic principles behind fuel cells / electrolyzers and show how potentiostats are used to qualify fuel cell and electrolyzer performance.

Read the article

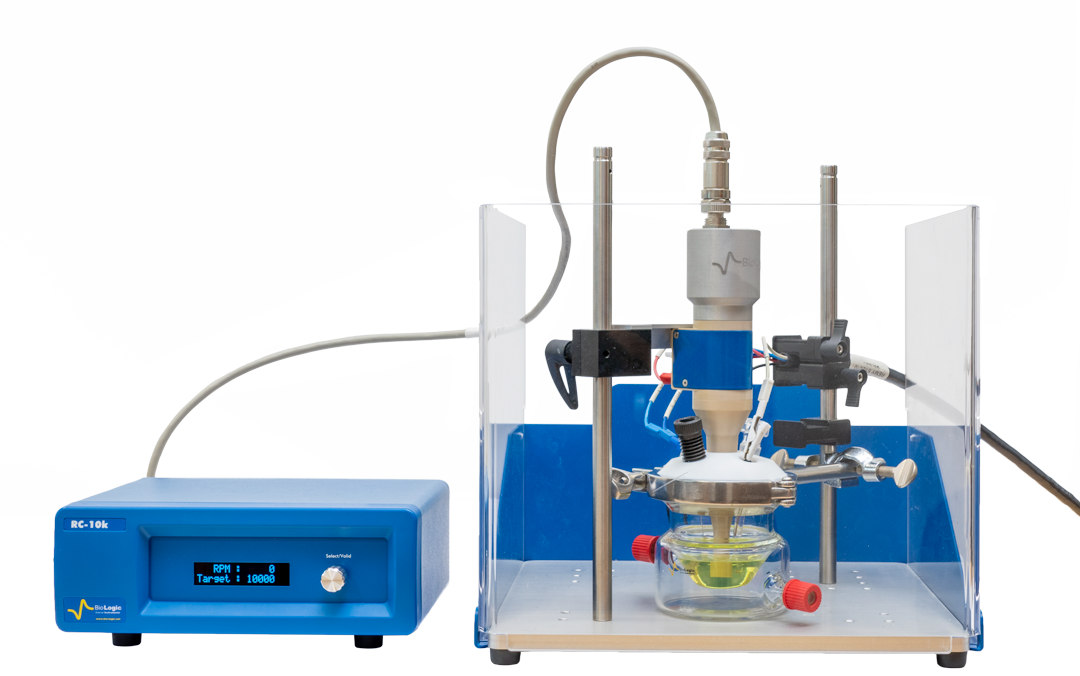

Read the articleWhy use RDE and RRDE method to characterize electrocatalysts?

This article explains how BluRev can help you understand electrocatalyst properties using RDE and RRDE methods