Ripple Measurement Insights: Elevate Battery Performance & Longevity

Latest updated: April 28, 2025Introduction

In modern energy storage systems, batteries are subjected to various electrical disturbances, including ripple currents. The ability to simulate these ripples is essential for testing battery durability and performance under realistic operating conditions. The objective is to mimic them accurately to study the effects of these disturbances on battery responses over time (battery aging through cycling) and optimize system designs. This is particularly important in electric vehicles (EVs), renewable energy storage, and industrial applications.

Ripple effect on ageing

Ripple currents are Alternating Current (AC) components, i.e. high frequency oscillations, superimposed on a Direct Current (DC) flow within a battery system. These ripples are typically generated by power electronics, including inverters, DC-DC converters, and rectifiers.

The main application field is the automotive industry with the design of battery packs and regenerating devices inside Electric Vehicles (EVs). The battery system can be exposed to high-frequency current ripples coming from the powertrain, leading to performance degradation and lifespan over time [1]. Real-world measurements have shown significant current perturbations ranging from 10 Hz to over 10 kHz on Hybrid Electric Vehicles (HEVs).

Figure 1: Typical series Hybrid Electric Vehicle (HEV) powertrain configuration. (Picture from the publication [1])

Studying the effects of these perturbations is also relevant for grid-connected Battery Systems or renewable energy storage (simulation of ripple currents to assess battery behavior under fluctuating energy input conditions).

Understanding ripple effects allows engineers and researchers to implement mitigation strategies, such as improved filtering techniques, advanced Battery Management Systems (BMS), and optimized power electronics design.

Measurement methodology and specifications

The methodology involves stressing the cell using an AC current ripple to study its impact on the battery over time. To achieve this, accurate ripple measurement requires a combination of high-precision instrumentation and well-established testing protocols. Both can be achieved by using BioLogic potentiostats/galvanostats, equipped with an appropriate current booster and EC-Lab® software.

NOTE: BioLogic premium boosters provide high bandwidth, resulting in clean, high-frequency sine waves.

The GEIS technique can be used to mimic an AC current ripple during charging and/or discharging of a battery.

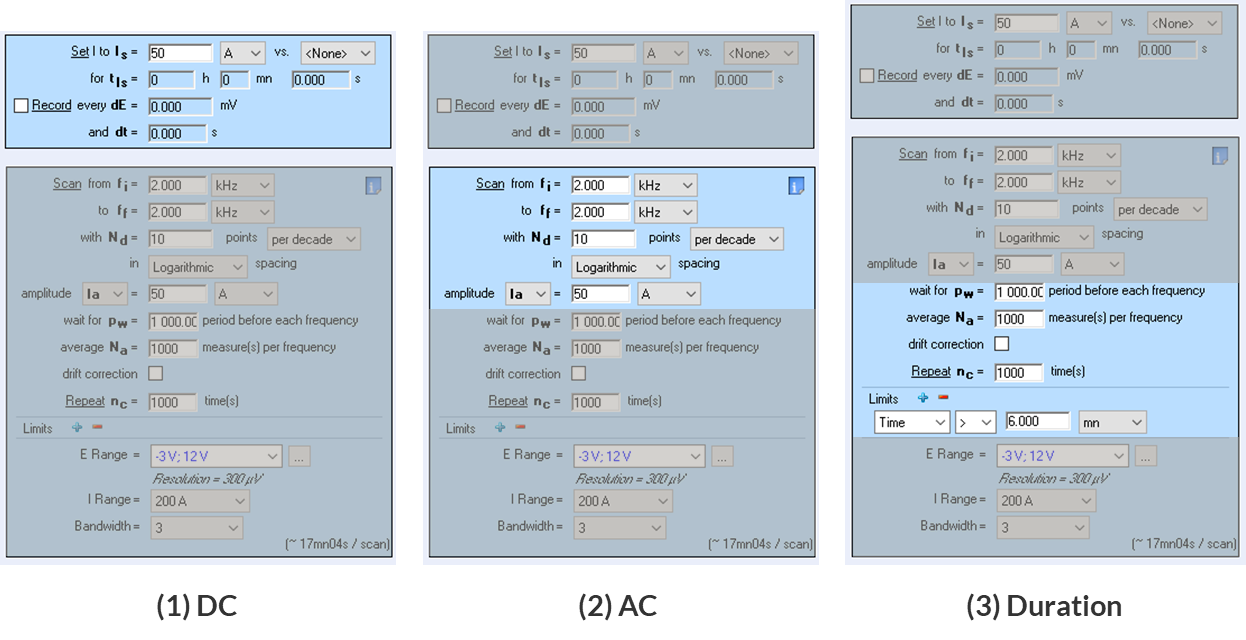

Figure 2: How to simulate AC current ripple measurements using the GEIS technique.

- (1) DC current value

- (2) AC current amplitude and frequency

- Use the same frequency for both fi and ff in order to apply a single frequency

- Choose the desired amplitude “Ia” (peak type amplitude).

- (3) Experiment duration and sinewave quality

- Add a limit by clicking on the “+” button. Select “Time” then enter the desired experiment duration.

- Continuous sinewave. Set Pw (wait time) and Na (averaging) parameters to the maximum values, which are 1000.

Conclusion

Ripple measurements are an essential aspect of battery diagnostics, providing insights into performance, reliability, and degradation mechanisms. By employing precise techniques and understanding their applications, engineers can enhance battery designs, mitigate degradation, and improve energy storage solutions across various industries.

References

- [1] Y. Zhang, R. McGreevy, and P. Jennings, “Ripple Current Effects on Lithium-Ion Battery Degradation,” University of Warwick, 2016. [Online]. Available: https://doi.org/10.1016/j.apenergy.2016.06.033.

- Keil, A. Jossen, and D. U. Sauer, “Aging of Lithium-Ion Batteries in Electric Vehicles under Ripple Current Influence,” World Electric Vehicle Journal, vol. 6, no. 3, pp. 532-542, 2015. [Online]. Available: http://dx.doi.org/10.3390/wevj6030532.

- P. Schmidt and M. Wittmann, “Impact of AC Currents on Lithium-Ion Batteries,” Batteries, vol. 8, no. 2, p. 11, 2022. [Online]. Available: https://doi.org/10.3390/batteries8020011.