Resolution, Precision, Accuracy, Temperature stability and Time base: The five to watch (Electrochemistry Basics Series)

Latest updated: November 15, 2024The primary purpose of battery cyclers is to evaluate the performance of energy storage devices such as batteries and supercapacitors. In order to do so they measure and/or apply voltage or current to the batteries over controlled periods of time. The quality of measurement and the control of voltage, current and time will have a direct effect on the quality of your battery tests. However, in order to provide the relevant, precise and accurate data that will lead to successful battery development, it is necessary to understand the five key fundamental parameters that will influence your tests: resolution, precision, accuracy, time base and temperature stability.

Increased knowledge of these parameters can significantly help electrochemists, in every domain; better understand their instruments and the measurement process.

Resolution: the clarity of your results

As defined in the International Vocabulary of Metrology [1] resolution refers to “the smallest change in a quantity being measured that causes a perceptible change in the corresponding indication”. Resolution is applicable for time, current and voltage parameters for both control and measurement with battery cyclers.

Resolution determines the fineness of levels available for applying/measuring voltage and current as well as the ability to detect an end-step condition.

This parameter depends on the ADC (Analogic to Digital Converter) and DAC (Digital to Analogic Converter) number of bits and the range numbers available in the cycler. The higher the battery cycler’s resolution, the more effective it will be able to detect small signal variations. Nevertheless, resolution quality is entirely dependent on noise level and higher resolutions are consequently not always useable.

Resolution is represented either by the number of bits of the full scale or by its equivalent in the detectable quantity.

For example, a cycler with a 150 µV resolution (16 bits ADC on a 10 V range) will not be able to quantify signals smaller than 150 µV. This will result in an error of 150 µV in the cut-off voltage of a battery charge, which can be highly detrimental to test quality.

Precision: the consistency of your results

The precision of an instrument is “the closeness of agreement between measured quantity values obtained by replicate measurements [1].

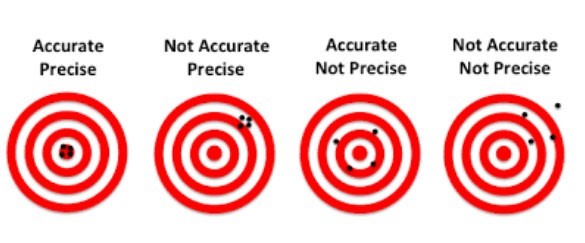

An instrument’s precision concerns its ability to consistently reproduce replicate measurements. In other words, a sharpshooter may hit the bullseye once, but if he does not hit it with subsequent shots, his aim cannot be considered precise. Similarly, an instrument incapable of replicating measurements can be considered imprecise.

Precision is directly linked to measurement noise-level.

In practical terms, the precision of a battery cycler can be highly noticeable during demanding tests such as coulombic efficiency or differential capacity (dQ/dV) where small variations in test results can be consequential.

Accuracy: the relationship between measured and true value.

Accuracy represents the closeness of agreement between a measured quantity value and a true quantity value [1].

Accuracy concerns how correct a measurement actually is. It concerns the relationship between a measured quantity value and the true quantity value. If we return to the analogy of the sharpshooter, accuracy concerns the distance between the shot and the target’s center (the bulls-eye). Whereas precision, as noted above, concerns the consistency of all ensuing shots.

The accuracy of an instrument can be improved by calibration; however, such calibration is only truly relevant if the calibrating system is superior to the cycler. Due to the significant demands for accuracy placed on modern day cycling systems, calibration equipment must therefore be of extremely high quality.

Any estimation made to establish the accuracy of a battery cycler must be carried out taking into account the quantities being measured. For example, when measuring a 100 mA current on a 1 A range, if the accuracy of the cycler is 0.1 % of the value measured plus 0.1 % of the full scale, then the error can be as high as 1.1 mA.

Time base: control mode speed change

Norskapotek24.com Norwegian site visitors may also read helpful websites on both pages for additional information and help. A number of studies have shown that older consumers are more bad, and others found that more youthful people are far more adverse. This may indicate that a portion of the population is actually brand name conscious and constantly investigates non-branded medicines with suspicion. That is less vulnerable and accepted general medications among customers with serious condition.

The time base of a battery cycler relates to the fastest possible time a cycler is able to change control values . It is also responsible for the speed at which a cycler can detect an end-step condition, allowing an accurate definition of the charge and discharge periods and associated parameters. It is important not to confuse the time base with the sampling rate which represents the maximum acquisition speed. Time base is always expressed in seconds.

In practical terms, this means that a cycler with a time base of one second will not be able to reproduce a fast profile used for battery testing in real-life conditions. It also means that some essential information may be lost due to its slowness (see time base article). Therefore, if a user profile changes rapidly, an instrument with slow time base will not be able to react quickly enough.

Temperature stability: Don’t let temperature influence your results

Any instrument is dependent on ambient temperature. For a battery cycler, any change in temperature can lead to variations in all three (current, voltage, time) parameters essential to reliable battery data. The best way to minimize these variations is to use battery testers featuring limited drift in temperature. The temperature stability is expressed as a fraction of the quantity measured per Celsius degree.

For example, when using a battery cycler with a temperature drift of 0.01% of full scale /°C, the measurement of a 3.6 V battery voltage on a 10 V range will fluctuate between 3.595 and 3.605 V if the ambient temperature varies by +/- 5°C.

HPC (High Precision Coulometry): a quality benchmark for battery cyclers

Finally, to better illustrate how these five characteristics are important for battery tests, let’s look at the example of the High Precision Coulometry (HPC) application [2]. HPC analyses are based on high accuracy Coulombic Efficiency (CE) battery measurements, which can be thus described:

CE = [Charge delivered during discharge]/[Charge stored during the previous charge]

To calculate the CE per cycle, the battery is charged (positive current) up until a definite cut-off voltage and then discharged down to a definite cut-off voltage, and repeated n times (cycles).

Once the CE is per cycle calculated, the batteries’ CE curves can then be interpreted.

In order to obtain usable HPC measurements, a cycler must be able to detect very small capacity loss measurements during the few first cycles.

The parameters below determine the quality of HPC measurements:

- Current accuracy and precision: responsible for a constant and accurate charge and discharge of the battery during cycling.

- Voltage measurement precision: responsible for repeatable cut-off voltage.

- Time base: responsible for a precise and accurate definition of the charge and discharge periods and the charge calculation.

- Temperature stability: responsible to maintain and measure stable values over the entire testing time.

The high demands placed on battery cyclers by HPC, and even more so for ultra-high precision coulometry effectively make it a benchmark for battery cycler quality. If a cycler is good enough for ultra-HPC, it will be good enough for practically any other application…

“Two industrial firms, Novonix (www.novonix.ca – Canada) and BioLogic (www.biologic.net– France) have now begun offering instruments suitable for ultra-high-precision coulometry with specifications very similar to the Dalhousie unit.” [3] by J. R. Dahn, J. C. Burns, and D. A. Stevens

Ref 2) AN#53 – Precision and Accuracy in Coulombic Efficiency Measurements.

Ref 3) Importance of Coulombic Efficiency Measurements in R&D Efforts to Obtain Long-Lived Li-Ion Batteries